Specialist in packaging machinery technology

We are a driven and reliable partner in the yeast and powder packaging processes

Over 20 years of experience

Welcome to Van Mourik Yeast & Packaging. With decades of experience in the high quality machinery and our excellent service we can call ourselves a specialist in packaging machinery technology. Our focus is on the powder dosing and packing and the yeast filtration and packaging.

Over 20 years of experience

Welcome to Van Mourik Yeast & Packaging. With decades of experience in the high quality machinery and our excellent service we can call ourselves a specialist in packaging machinery technology. Our focus is on the powder dosing and packing and the yeast filtration and packaging.

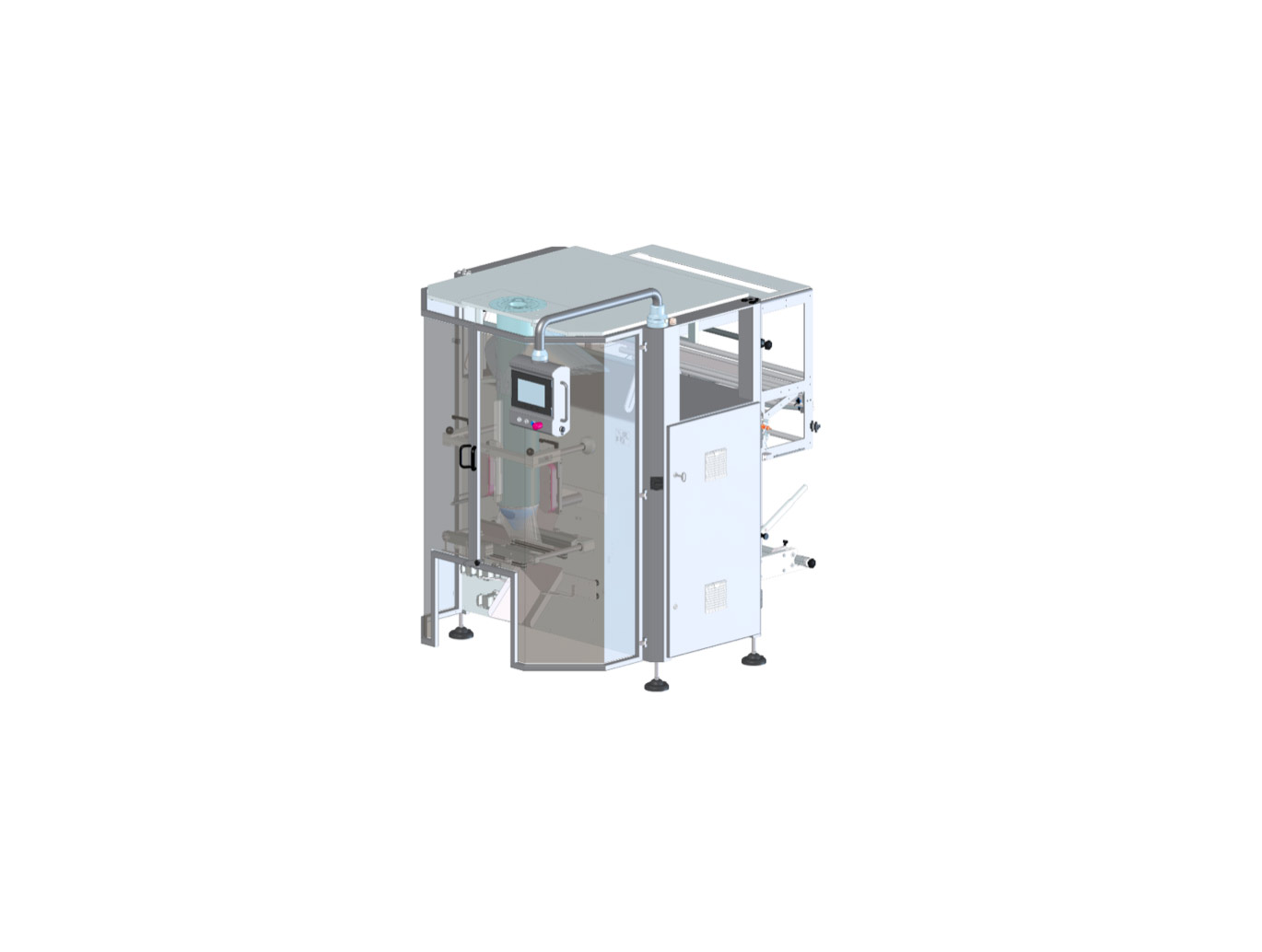

Yeast

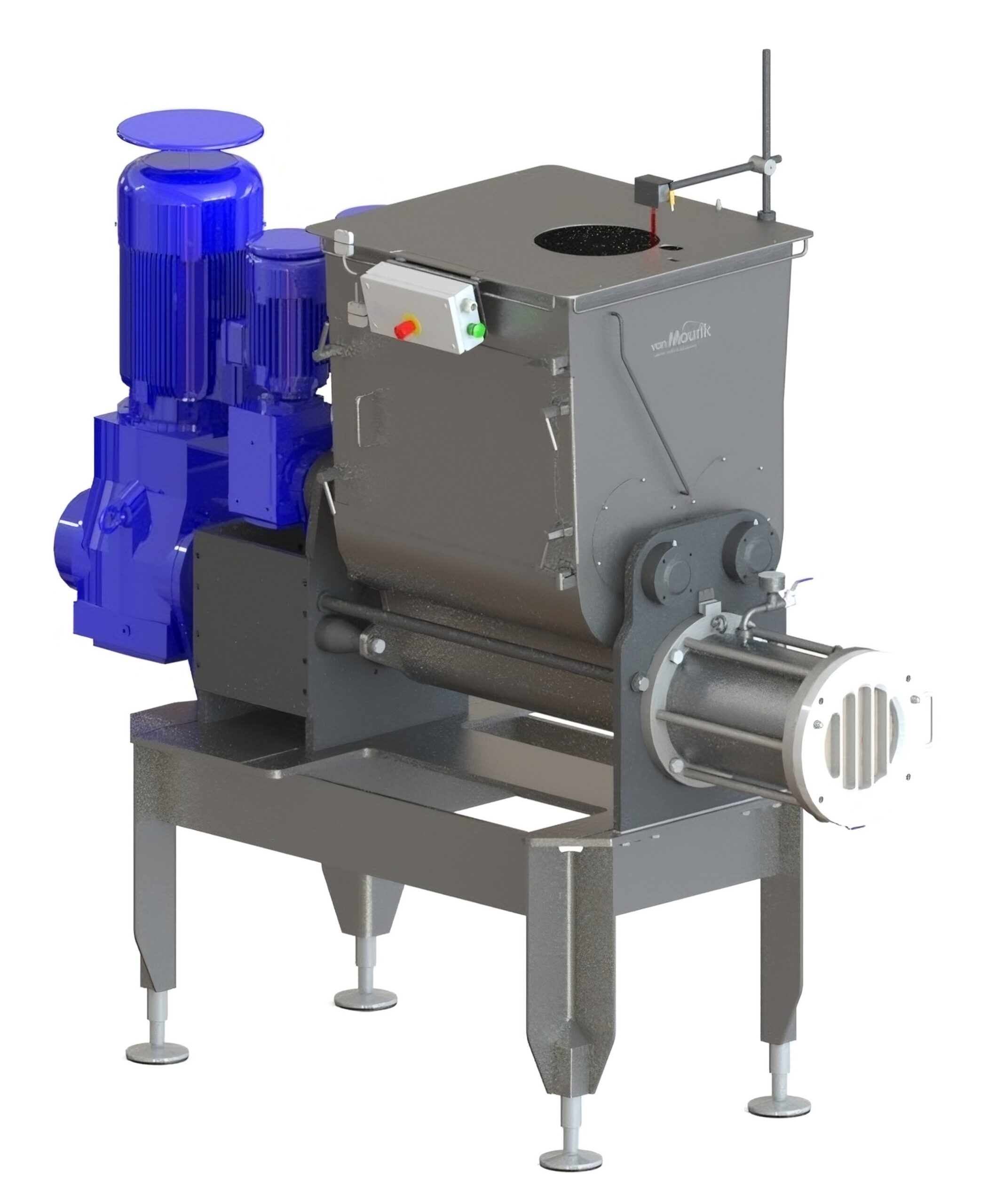

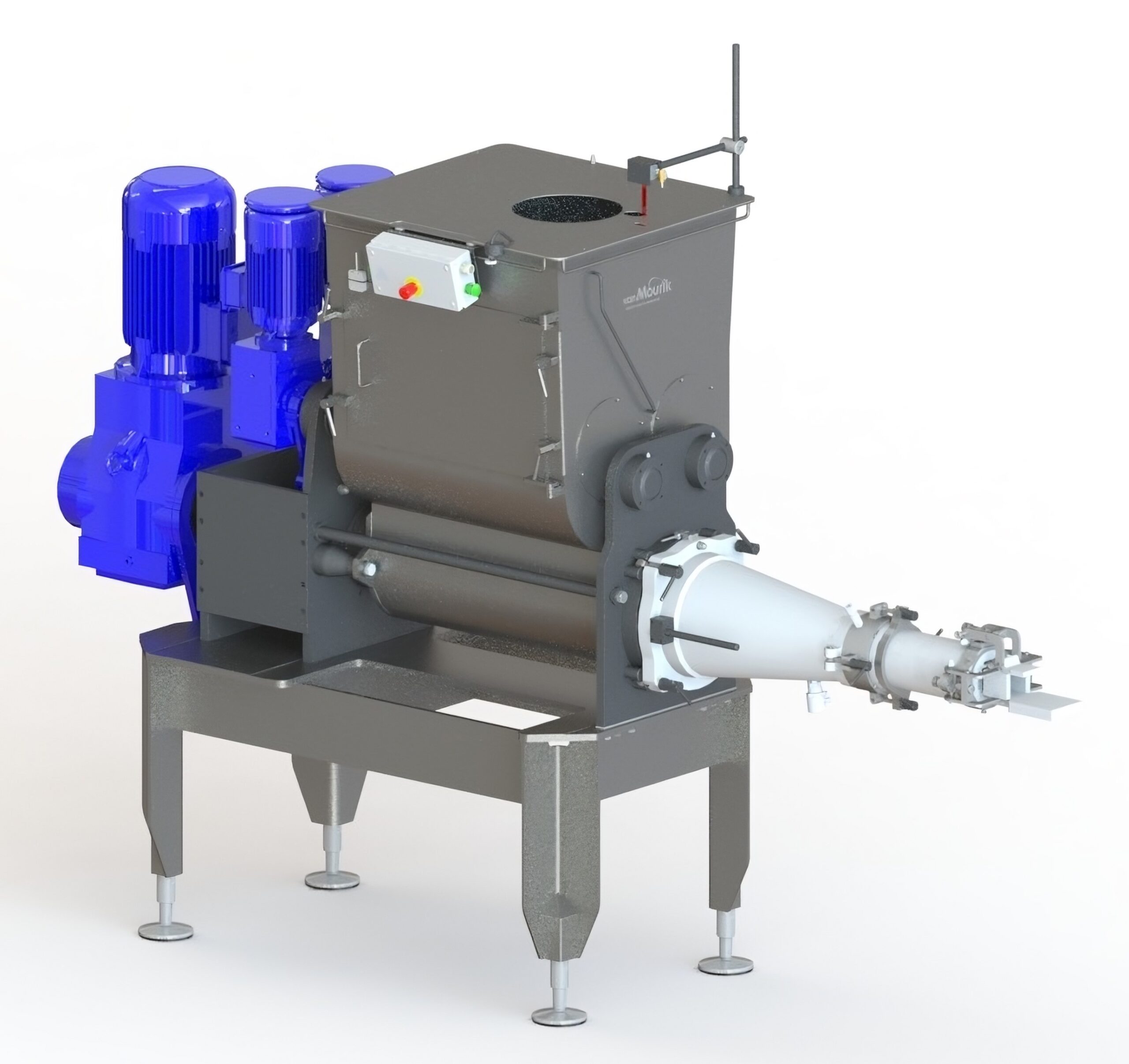

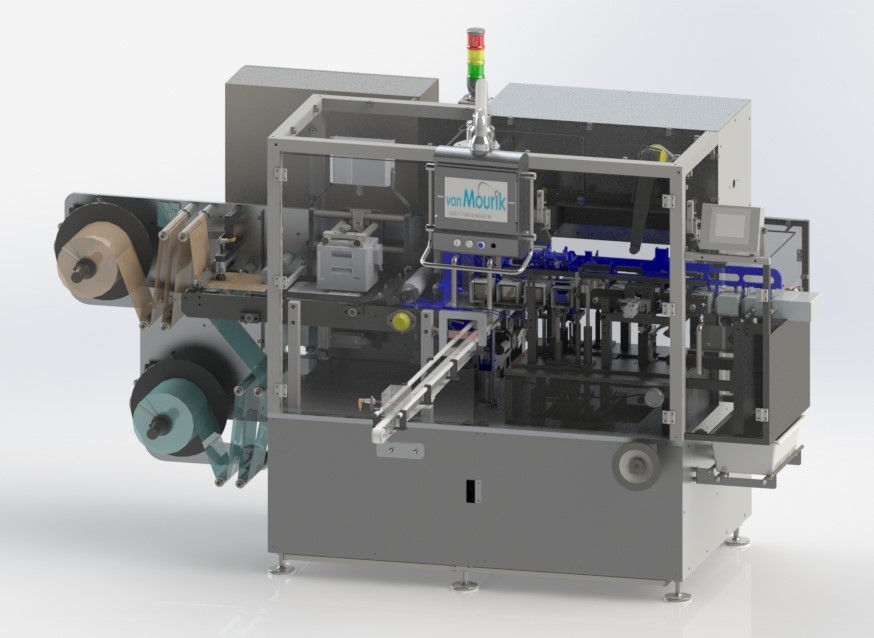

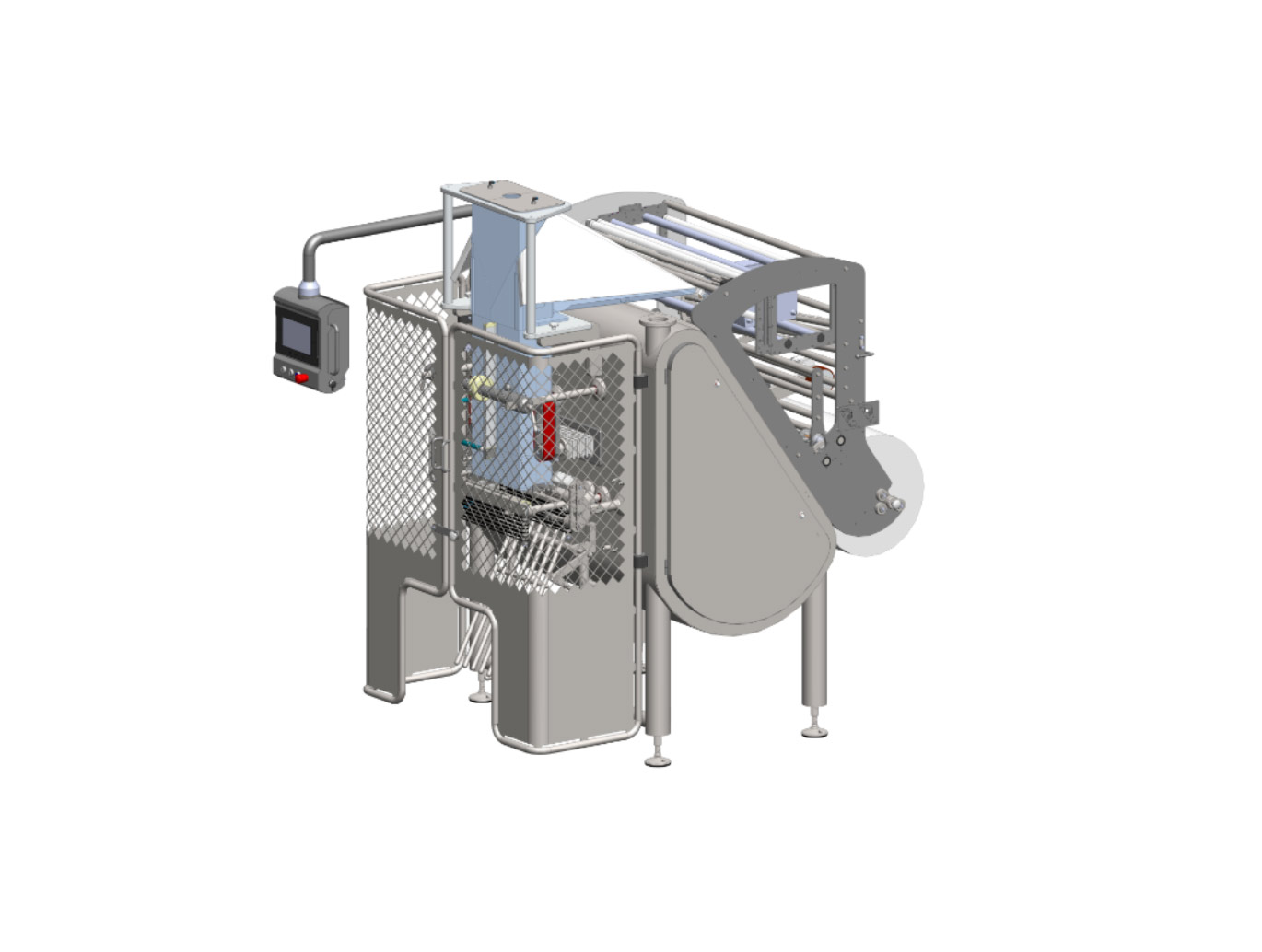

Yeast, an important ingredient of bread, influences the flavour and airiness. Our scope of supply starts after fermentation and ends at the packaging. As you can see below we have machinery for the following processes, which starts with the filtration of water out of the liquid yeast. After that yeast will be ready for packing this into blocks from extruder, cutter to wrapper, the bagging through a vertical form fill seal machine (VFFS) or extruding of noodles.

Filtration | Noodles | Blocks | Bagging

Hygienic Design

We implement hygienic design to avoid contamination and more effective cleaning

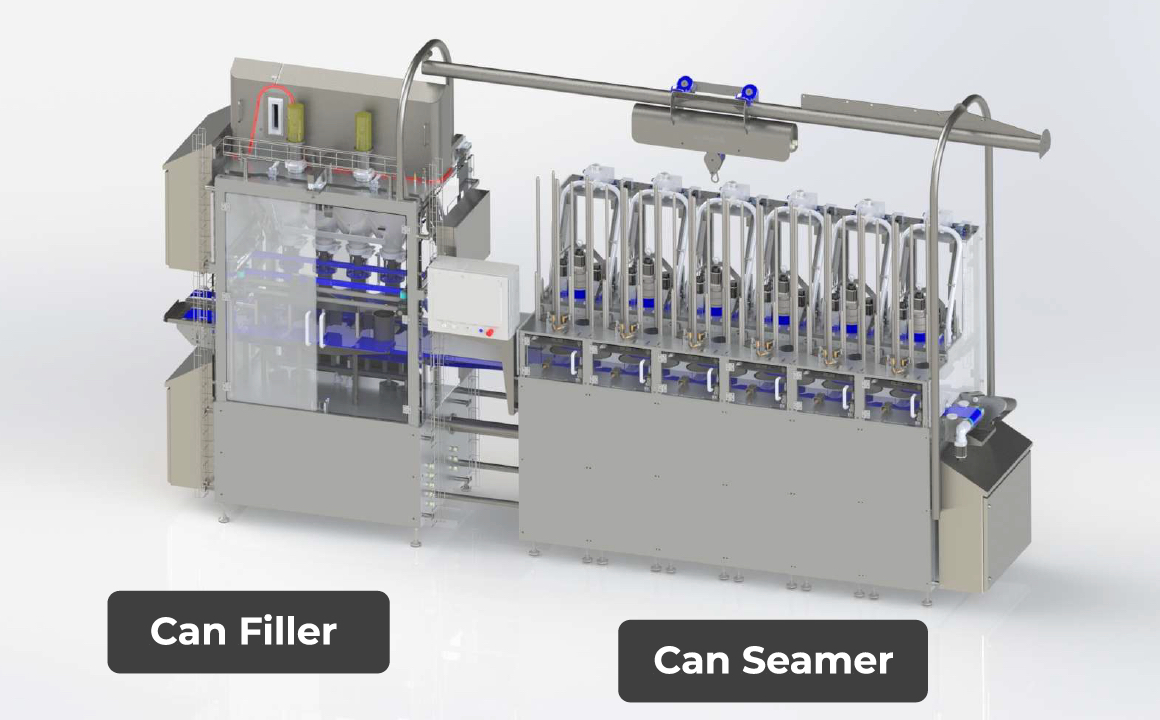

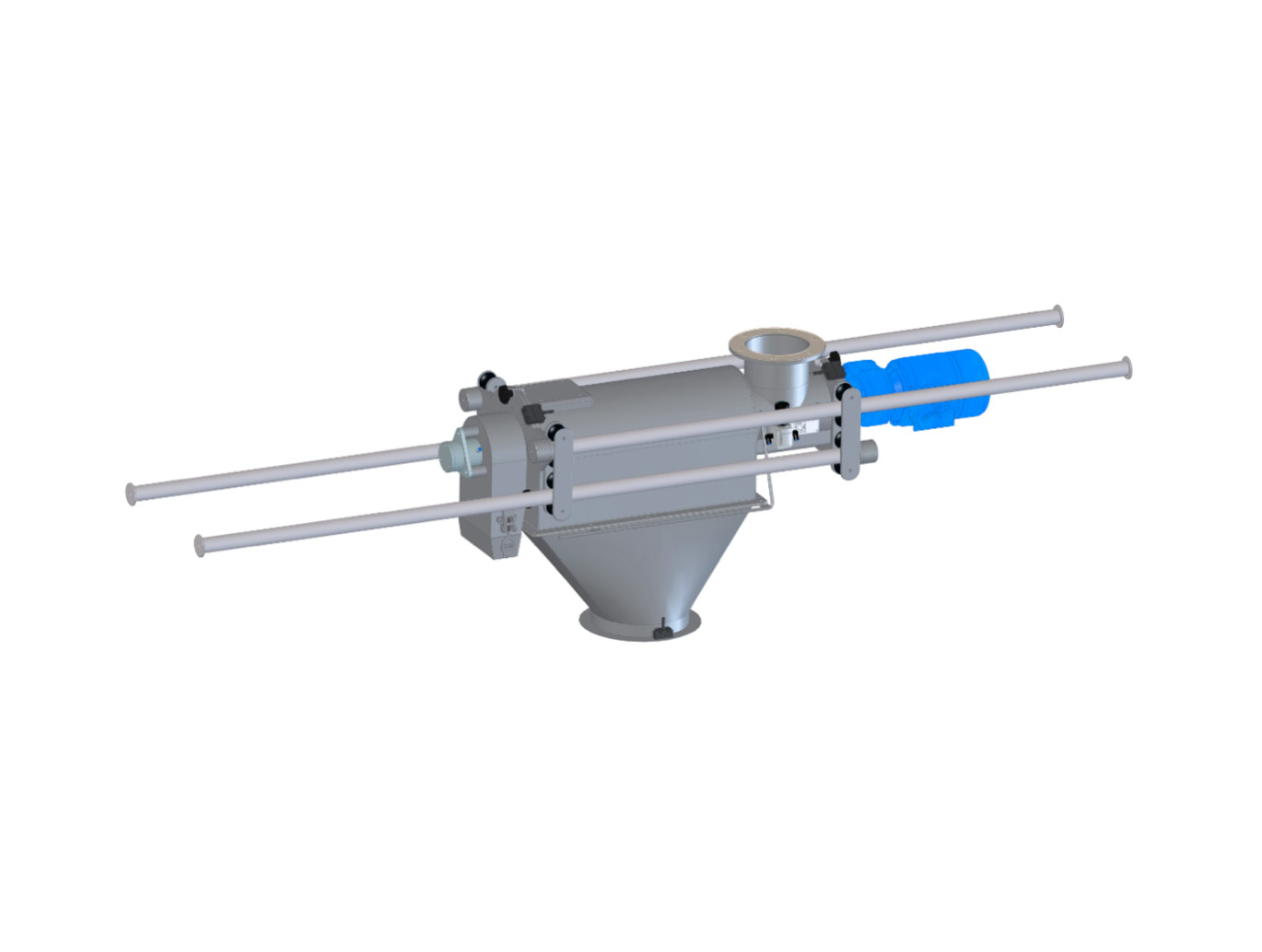

Powder

‘Powder’ is for Van Mourik Yeast & Packaging a collective name for milk powder, spices, herbs and bakery ingredients and several more. For these markets we develop and produce a wide range of dosing and packaging machines. Our machines stand for accurate sieving, dosing and bagging as well as for product handling systems.

Canning Machinery | Sieving | Dosing | Bagging

Machine management

We offer remote service support for a real time analysis of the process.

Martin Dannenberg

For sales related questions

please contact me.

Frans Lijbers

For support and technical

questions.

Diana Bouman

Just for any general question.

Vacancy

Trainee

Passion for technology and precision in every movement.

We’re a High Tech machine producer in the food industrie. We make high level machines with the emphasis on quality and hygiene. Are you looking for a traineeship in mechanical or electrical engineering?

Then we’re looking for you!

What to expect from us?

- A diverse job in an high tech environment.

What would we like to see?

- A passion for technology.

- The wish to learn and grow.

- Based in the vicinity of Van Mourik Yeast and Packaging.

Would you like to learn more?

Please contact Diana on 06 5073 2205 or email yp@vanmourik-group.com

We’re looking forward to it.

Service on location

As Van Mourik Yeast & Packaging, we can help you focus on your main priority: producing and selling high quality products. To assure product quality, low maintenance costs and flexibility we offer several technical services.

Leave a message

Contact us

Do you have any question about a project or a general question?

Just call or e-mail one of our team members above.

Do you have a machine trouble outside workinghours?

Please send an email to support.yp@vanmourik-group.com

Office info

Our head office with production site is located at the Boylestraat in Ede (Netherlands), in an easily accessible location along highway A12.

![]() Boylestraat 36a, Ede The Netherlands

Boylestraat 36a, Ede The Netherlands